Power steering racks

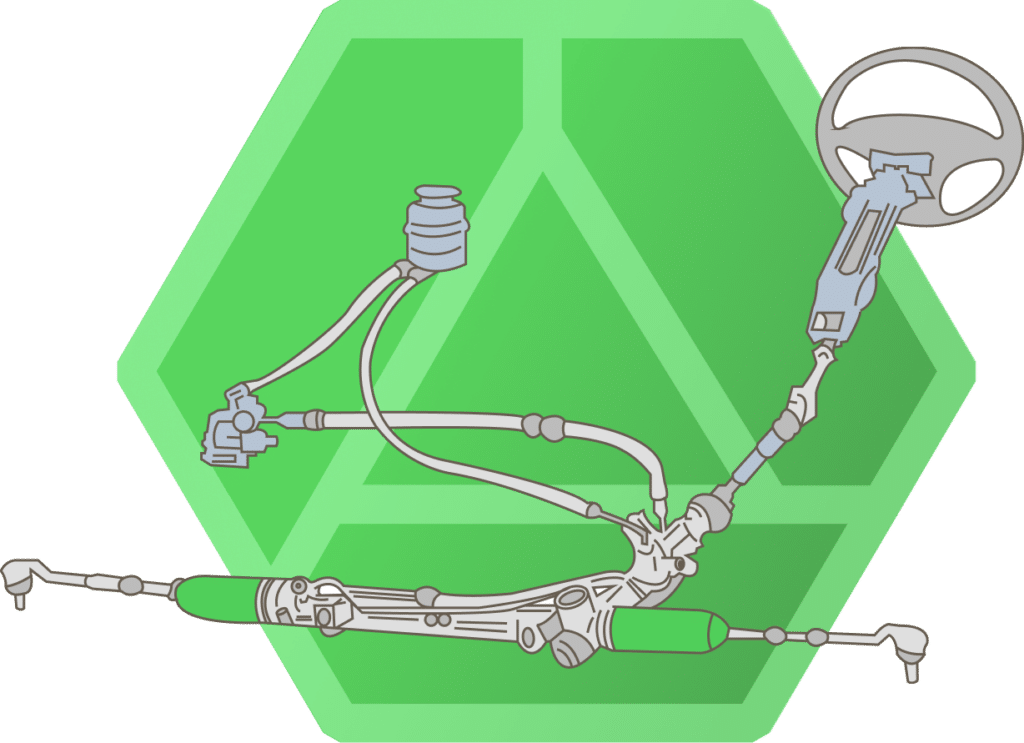

The role of a steering rack

The role of a steering rack is to enable the driver to change direction with a minimum of effort on the steering wheel.

The power steering rack, also known as power steering, is a mechanism that reduces the force required to turn the car’s wheels. It makes steering more comfortable, especially at low speeds and when parking.

Hydraulic power steering: Most commonly found on older cars. It consists of a hydraulic pump driven by the engine belt system, which pumps hydraulic fluid into the steering rack. When the driver turns the steering wheel, the valves in the rack open, allowing the fluid to flow, creating a force to assist steering.

Electric power steering: A more modern solution that replaces the hydraulic pump with an electric motor. Sensors monitor the movements of the steering wheel and the speed of the vehicle, and the controller adjusts the electric motor accordingly to assist in turning.

Construction of the power steering rack

- Expansion tank

- hydraulic return pipe

- pressure hose

- hydraulic gear

- hydraulic steering pump

- hydraulic hose

Causes and symptoms of rack and pinion failure

Damage is most often caused by the road conditions and the way the vehicle is driven. Unsuitable road surfaces, frequent wheel spin, driving over high kerbs, incorrectly fitted rims and tyres – these are the main causes of steering rack failure.

Symptoms of failure include leaks from the steering rack, increased resistance to turning the wheels – or a lot of free play on the steering wheel, increased noise from the steering and even locking of the steering wheel. Most of these symptoms occur gradually and are therefore easy to underestimate or ignore. In most cases, however, it is possible to act in time to prevent major damage.

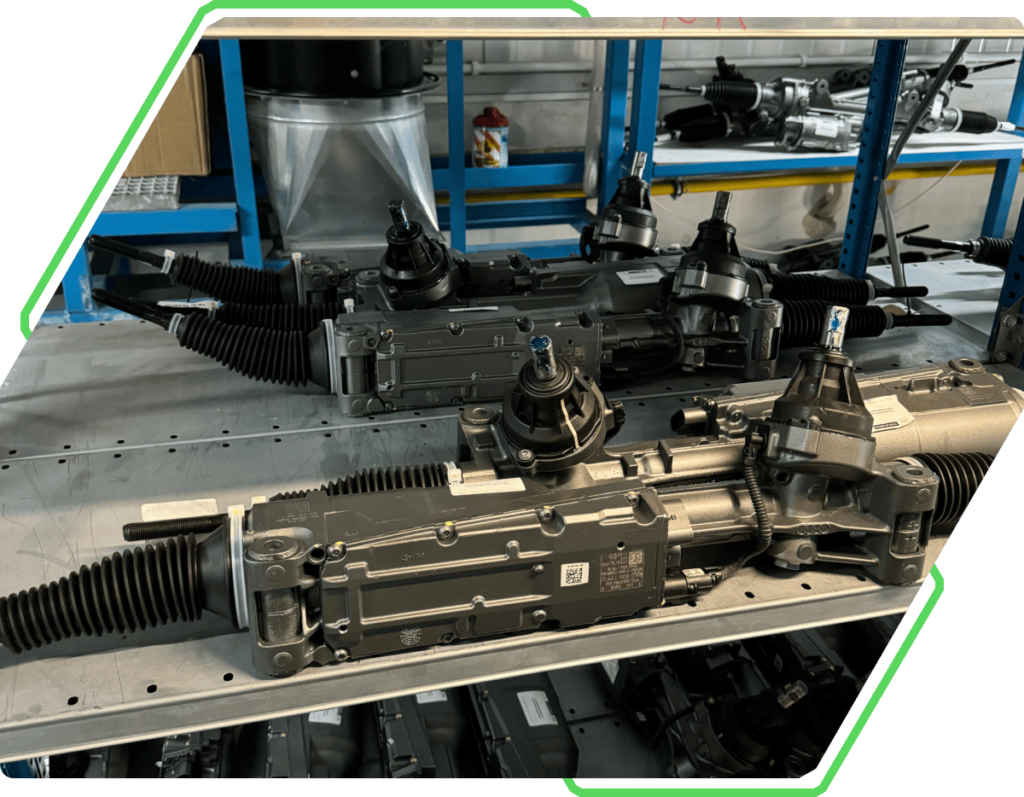

Many steering axles used in cars have a life expectancy of 10 years or 200,000 km, but there is no rule – what matters is the durability of the model in question and its correct maintenance. The life of this component can be extended by remanufacturing.

The most common steering rack faults

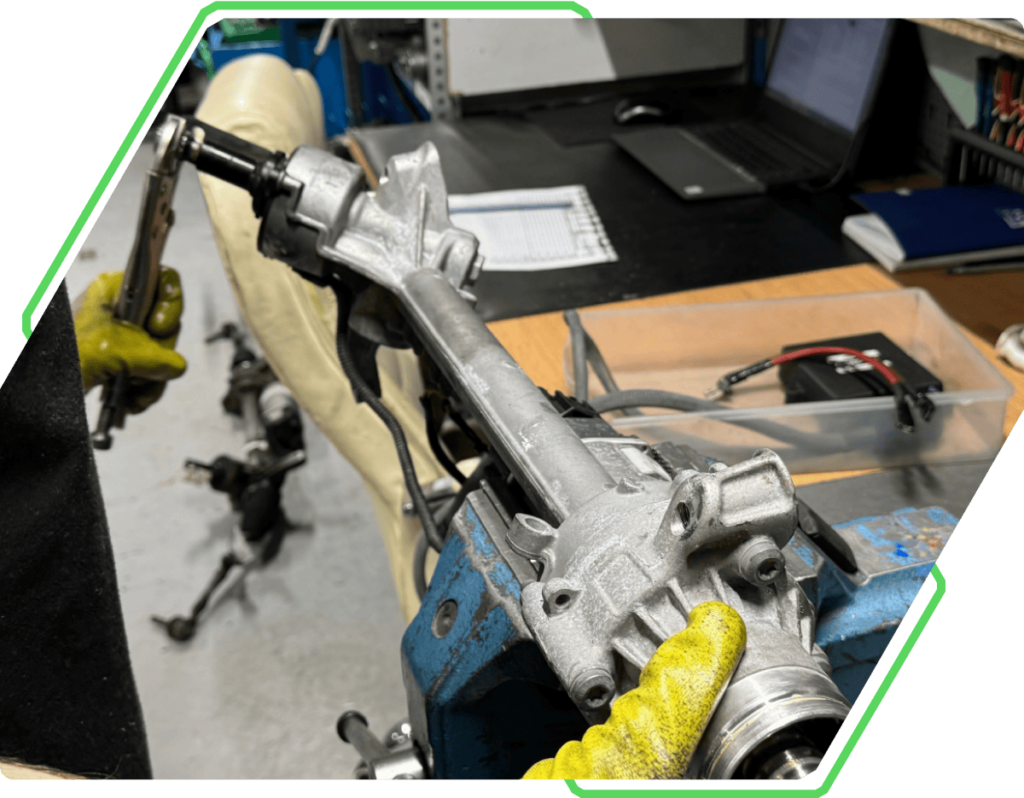

How is the steering rack remanufactured?

Natural wear of the steering rack can be reversed by remanufacturing. Only permanently damaged components require complete replacement. Only a professionally carried out remanufacturing will ensure many years of service for the vehicle. The best specialist remanufacturing facilities begin the process of restoring the steering rack to working order by disassembling the subassembly, cleaning the individual parts and replacing the damaged components with new ones. Once the rack and pinion unit is reassembled, the most important process follows – professional testing.

The factory remanufacturing process is divided into many stages, the most important of which are:

- Pre-wash

- Removal of covers and rod ends

- Roto-vibratory cleaning

- Disassembly

- Ultrasonic cleaning

- Component remanufacturing

- Component verification and selection

- Assembly preparation

- Ultrasonic cleaning

- Assembly

- Pneumatic test

- Hydraulic test

- Assembly of covers, marking

- Painting

How much does it cost?

- Depending on the type of rack and pinion unit, remanufacturing takes 2-3 days and the price varies between 400-800 PLN.

- On the other hand, we pay 800-1000 PLN for a steering rack remanufactured in the factory, but the quality of the product is definitely 100%. Of course, this price does not include assembly costs.

- A new steering rack is very expensive, sometimes up to 10.000 PLN. As you can easily calculate, in most cases remanufacturing with reassembly is the most attractive option. However, it is worth using only professional workshops that specialise in this field. Our safety on the road is more important than a low price.