Alternators

What is an alternator?

Every combustion engine car has an alternator. Without it, the battery would quickly run out of power, the engine would stop and the car would not start. What is an alternator and how is it built?

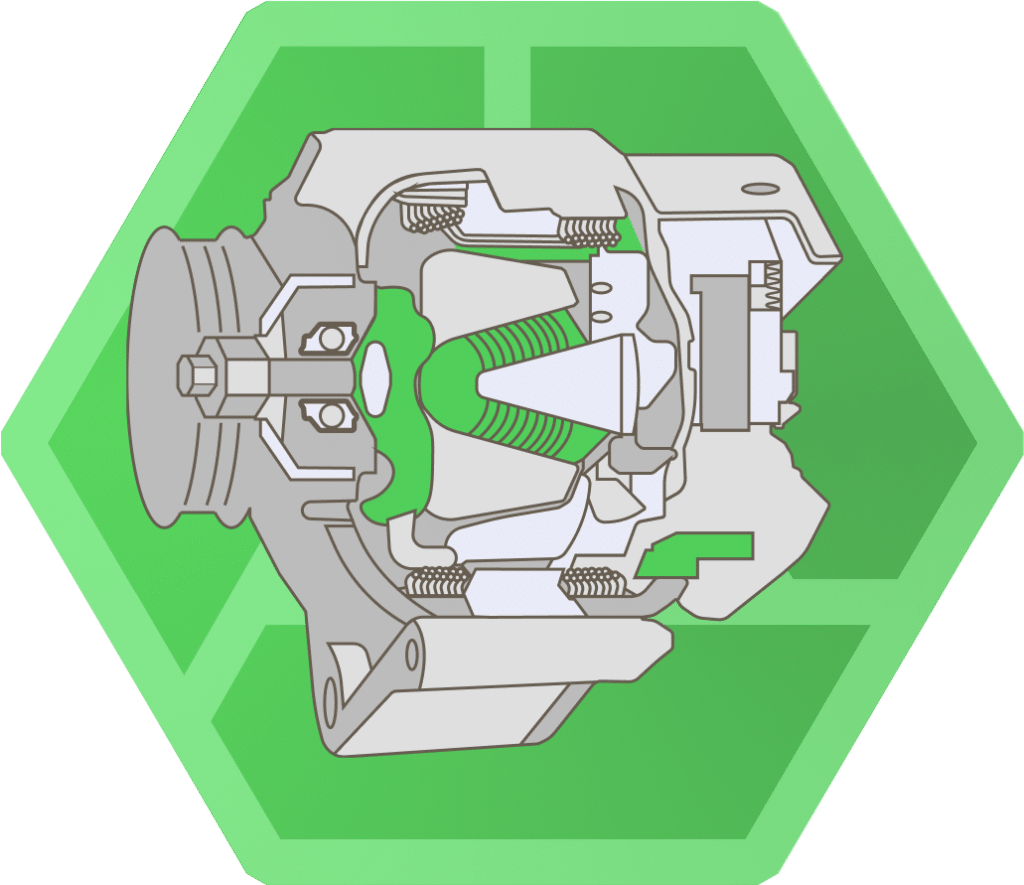

An alternator is a generator of alternating current, often three-phase. It is used to convert mechanical energy into alternating current. In an alternator, current is generated in the stationary stator wiring by the rotating magnetic field of the rotor. It is commonly used as a power source in motor vehicles.

To ensure operation with a battery that requires DC voltage, the alternator has a built-in rectifier on silicon diodes and also contains a built-in voltage regulator.

The alternator consists of:

- Front bearing,

- Pulley,

- Stator,

- Rear bearing,

- Slide ring,

- Regulator,

- Rear cover,

- Diode plate,

- Housing,

- Rotor,

- Front housing

How the alternator works

The alternator is mounted on the engine in a position that allows easy connection to the crankshaft by means of a multiple V-belt or a V-belt. The main components of the alternator are a fixed stator and a rotor. The stator consists of an insulated steel frame surrounded by wiring and the rotor is driven by brushes and slide rings. Electricity is generated when the rotor rotates within the stator, creating a magnetic field and producing an alternating current.

Most common alternator faults:

Loud operation of alternator

- Worn bearings – excessive free play

- Defective alternator freewheel

- Short circuit in the stator wiring

- Loose alternator

- Loose alternator belt

Charge indicator does not turn off

- Blown charging circuit fuse

- Faulty alternator rectifier board

- Charging circuit cable defective

- Broken V-belt

- Defective freewheel pulley

- Defective voltage regulator

- Defective stator wiring

Flashing charging indicator

- Worn brushes

- Worn slip ring

- Defective freewheel pulley

- Blocked brush

No charging

- Defective voltage regulator

- Short circuit between rotor wiring

- Short circuit between stator coils

- Damaged diode plate

- Not properly tensioned belt

Light bulbs keep burning out

- Defective voltage regulator (excessive charging)

How is the alternator remanufactured?

The most cost-effective way to repair an alternator is to replace it with a remanufactured one. Why? There are many advantages to this solution. Firstly, the price – remanufacturing is usually cheaper than buying a new alternator. Second, remanufacturing takes place in a professional facility, which guarantees a high-quality repair and often includes a warranty on the remanufactured product. Thirdly, remanufacturing is more environmentally friendly than manufacturing new alternators. Fourthly, the market for remanufactured parts is based on a circular economy system, which reduces the waiting time for a remanufactured alternator.

Standards for remanufactured alternators

- Housing threads – corrected or replaced with new ones. Repaired with thread inserts where necessary.

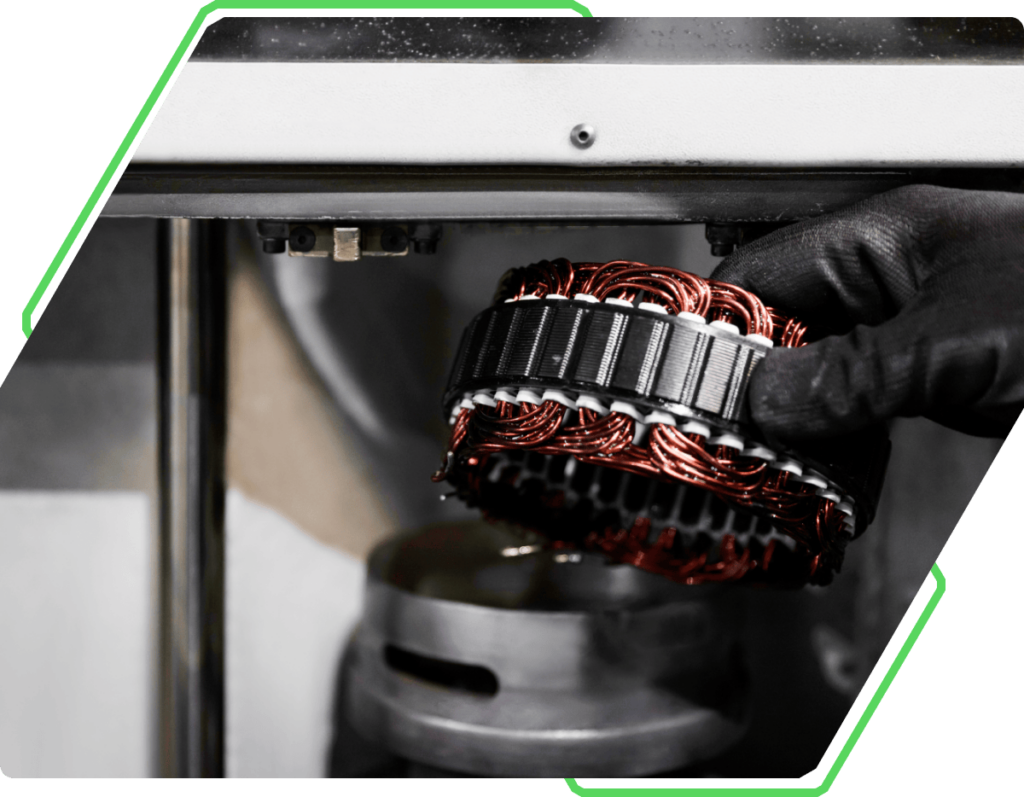

- Stator – inspected and replaced if punctures or short circuits between wires are found. Cleaning and maintenance.

- Rotor – inspected, cleaned and serviced. Replaced if punctures or short circuits are found between coils. Slide rings brought to nominal condition as specified by manufacturer.

- Regulator – checked and cleaned. Brushes, springs or complete component replaced as necessary.

- Diode bridge rectifier – tested, diodes or complete component replaced if necessary.