Rivolv’s product range

Why our products?

Our range includes both factory remanufactured and refurbished parts. These products are comparable in quality to a brand-new product and are always better than a cheaper replacement which may be of unknown origin.

However, to be sure of a good product, it is worth buying parts from professional remanufacturers – it is more cost effective. And that is what Rivolv offers – good quality products from proven suppliers with many years of experience in the market.

An economical and durable alternative

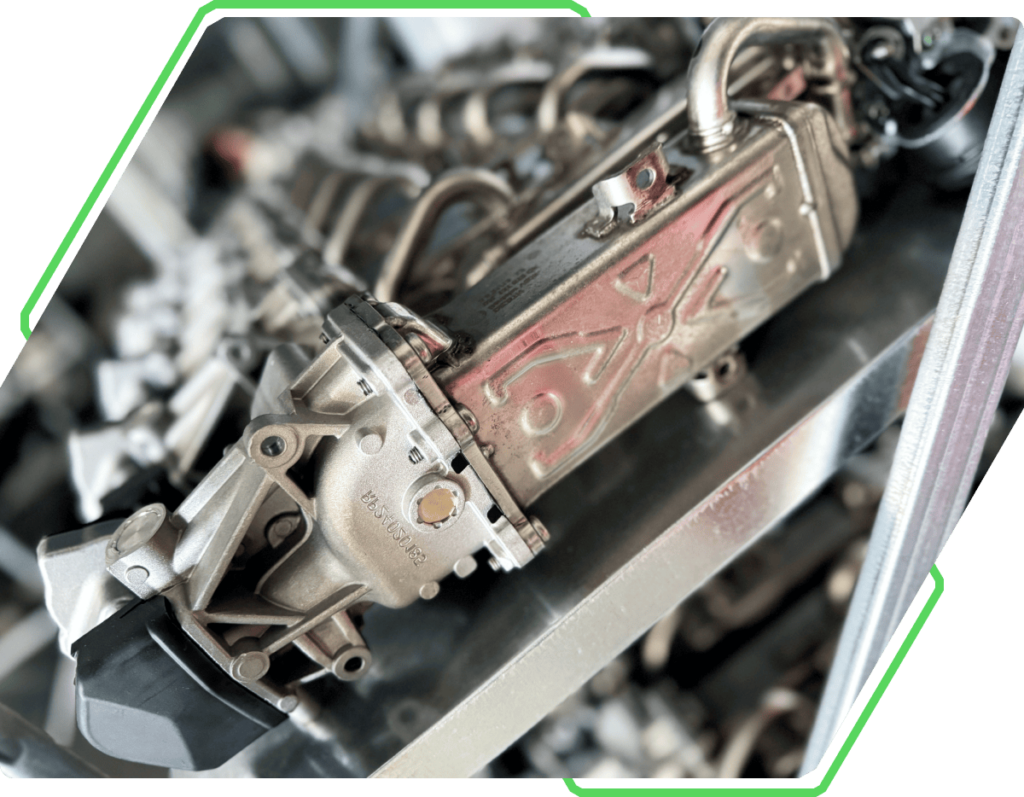

Whether you are buying an alternator, an EGR valve or a steering rack, regardless of the age of your car, remanufacturing such components is always attractive in terms of cost.

For older cars, there may not be a suitable replacement on the market at an attractive price. For users of newer vehicles, remanufacturing maintains the quality of the vehicle – the remanufactured component will not only be cheaper, but also more robust. In addition, a remanufactured part will always perform better than a cheaper replacement of unknown quality.

Key to sustainable use of resources

The exploitation of the earth’s resources is already at a high level. Some scarce raw materials are becoming part of the political game. Public awareness and governments’ responsibility for the environment is also growing. This is where remanufacturing comes in. The reuse of car parts means less exploitation of raw materials, less energy input with a symbolic contribution of waste.

Remanufacturing is based on a closed-loop system that uses only the materials that are needed. Very often the remanufacturing of a component consists of appropriate cleaning, repair or replacement of worn parts, installation of new parts and… providing a warranty as with new products.

Rivolv’s product range

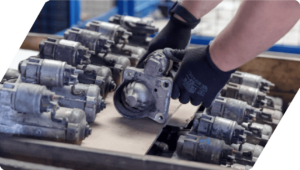

Thanks to our precision remanufacturing process, we offer top quality components that have passed rigorous testing and meet all safety standards.

The process of remanufacturing parts

-

01

01Basic core inspection

Initial inspection of the part removed from the vehicle based on acceptance criteria to determine reusability and possibility of remanufacturing.

-

02

02Disassembly

Disassembly of all parts into components. Any products with cracks, faulty joints, severe corrosion, etc. are rejected.

-

03

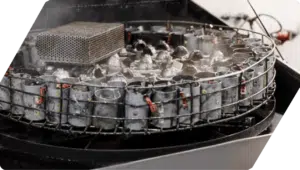

03Cleaning

All reusable parts undergo a rigorous ultrasonic and chemical cleaning process.

-

04

04Re-inspection

Complete inspection, measurement and testing of individual components to ensure compliance, both visually and using appropriate test equipment to determine if tolerances are within acceptable limits.

-

05

05Replacement of the part

Replacement of all wearing parts in line with OE specifications with the same as OE ones. Components that cannot be given a second life are discarded.

-

06

06Reassembly

Units are reassembled to OE approved specifications and assembly procedures.

-

07

07Testing and calibration

All units are 100% tested, verified and coded according to requirements and OE standard. This is the final stage of remanufacturing.